Solar Smart Greenhouse Controller

Uses state of the art Artificial Intelligence to control, optimise and diognose fruit and vegetable plants grown using deep learning and hydroponic technology. Currently under development... Available 2022

Power Smart Greenhouse Controller

Planned development for 2023

Bar Tender

Planned development for 2023

Aquarium Doctor

Planned development for 2023

Hot Tub Doctor

Planned development for 2023

StarLock

The Starlock fixture was designed to automate the process of fitting starlock washers to the pivoting rod that allows you car seats to be adjusted. This machine would be held by the operator and moved over the edges of the seat at which point the operator would press a two hand start buttons to begin the fitting sequence. The washers would be tightly fit to each end of the rod with a clearance of 0.4mm which was then tested by a LVDT poke-e-oke to test the clearance there and then whilst giving the user an indication of the measurements and whether the starlock washers have been installed to a pass or fail level depending upon a configurable tolerance of a small HMI mounted on the actual machine.

Tilt&Turn

I developed this software using GX Developer Ladder Logic with the purpose of assisting welding of large MRI Magnetic Coils for Siemens body scanners. The Machine consisted of a servo drive to raise and lower the coils to a specific height with an accuracy of 1mm and allow them to be manipulated by tilting forward or backwards as well as rotating the coil. The machine was operated by a series of push buttons and selector switches mounted on a control panel that illuminated certain buttons depending upon the current state of the machine in order to prevent operator errors.

EVA Trimm

As well as working directly for sharp on a variety of there solar panel production machines I also developed the software for their EVA Trimming Machines. The EVA trimming machine was programmed to convey solar panels into the machine where they would be lifted and then each side would be precisely cut removing the edges of the lamination that protects the solar panels from weather damage. A HMI was also developed for this project to display production data and alarms that notified maintenance of any problems that may arise such as broken cutting blades or misaligned solar panels. Additional manual functions for this machine was also implemented to move the cutting blade inverters to either their start position or a home/park position in order to allow broken blades to be safely replaced.

Advanced Hydraulics

This system was designed to intelligently monitor the load on hydraulic pumps necessary for powering several large scale engine cylinder head casting production plants. The purpose of this system was to make their hydraulic systems more energy efficient by choosing which pumps to turn on at any time depending upon the demand. The HMI displayed pump status and warnings for whether the hydraulic fluid was critically low or overheating and well as allowing the operator to manually select pumps to operate or intelligently deciding which pumps to use depending upon the thermocouple temperature readings. The operator could select all of the thermocouples or choose specific thermocouples to take an average of the actual system temperature in order to reach the configurable temperature set point.

Pipe Leak Test

The Pipe leak test was programmed to test Honda car exhaust pipes for leakages in order to ensure the highest quality of manufacturing was maintained. The pipes were manually loaded onto the machine and the operator would press the start button, the appropriate sequence for each of the 20 different variants would then be called to operate a series of pneumatic cylinders in order to seal the pipe. The pipe would then be pressurised for a configurable fill time, settle time and testing time with a highly accurate pressure set point. All configurations and selecting of the variant type was able to be selected by the operator on a HMI which also showed live information of the analogue pressures and current step of the sequence being run with any faults also being indicated. A final pass or fail lamp would be illuminated depending on whether the pipe passed the pressure test within a configurable tolerance level.

Robotic Dementia Medication Administration System

A variation of the ASPEC system described below is used to deliver patients medication when required and aims to reduce the number of missed medications that may be inherent due to the patient forgetting to take their medication due to a mental condition such as dementia. The system intelligently adapts the medication schedule within safe pre-prescribed limits. Patient biometrics are also monitored and incorporated into the control actions to maybe aleart a nurse if their blood pressure is too low.

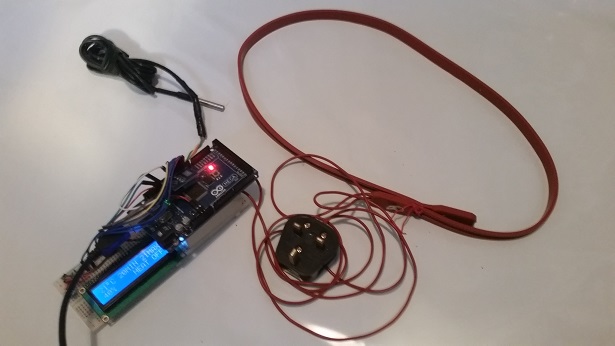

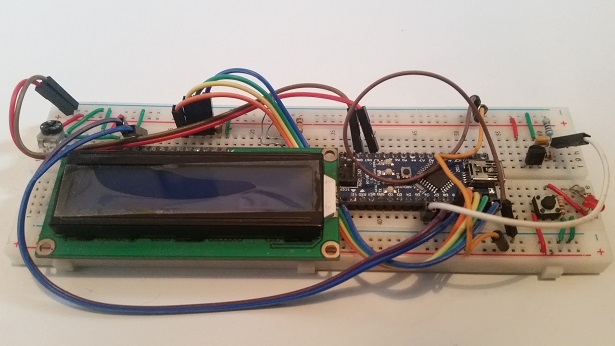

Home Brewing Controller

Simply select what type of alcohol you are brewing (Vodka, Wine, Cider, Beer) and this system controlls the fermentation temperature using a heating belt around the fermentation vessel. Using a real time clock this system allows staggered temperature changes to occur within the limits of the yeast being used. For example, the first day of vodka brewing should be 14 deg C and then on the third day it is increased to 16 deg C, finaly by day 5 the temperature should be 18 deg c andthen constantly maintained at this temperature regardeless of the ambient room temperature otherwise your brew may be too sweet.

ASPEC

The "Automated Solar Programmable Enviromental Controller" is capable of both monitoring enviromental conditionas such as temp, humididty, PH, EC and acting appropiatly to maintain optimal crop growth conditions. The system can dispense up to 6 different nutrients as well as controling the temperature of the nutrient solution and ambient air temperature.

|